Features

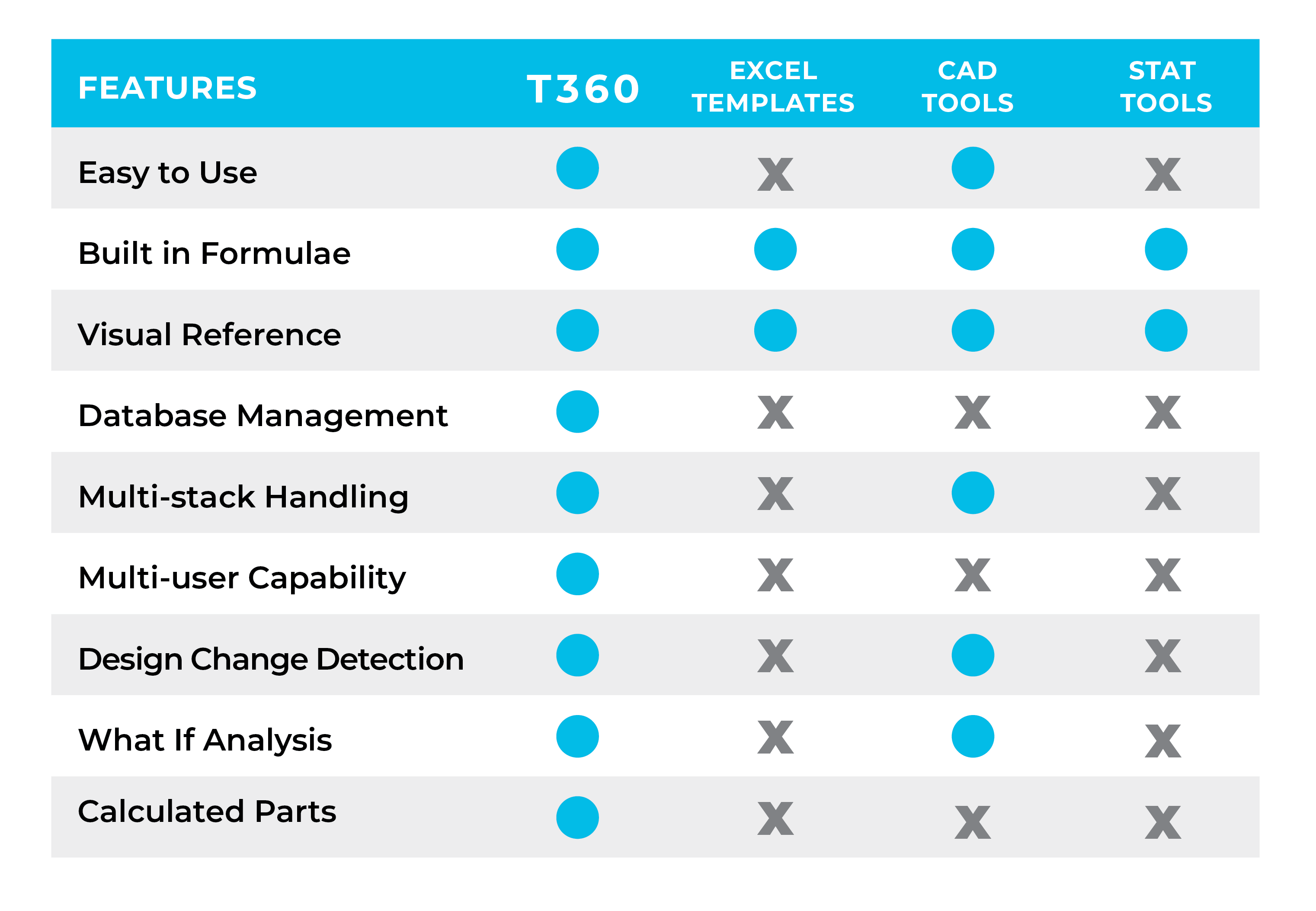

Tolerance 360 is a feature rich application that saves design engineers hundreds of hours of work.

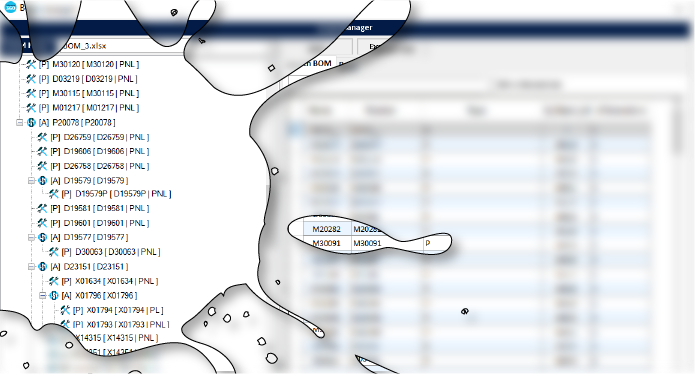

Tolerance360 seamlessly integrates all aspects of tolerance analysis – from design to manufacturing to quality engineering. The System manages and automatically updates part design, actual inspection data, and tolerance analysis results to drastically improve design process efficiency by connecting the dots between CAD design, manufacturing, and quality assurance.

Highlights

Errors

%

Increase in Productivity

Saved Money/Year

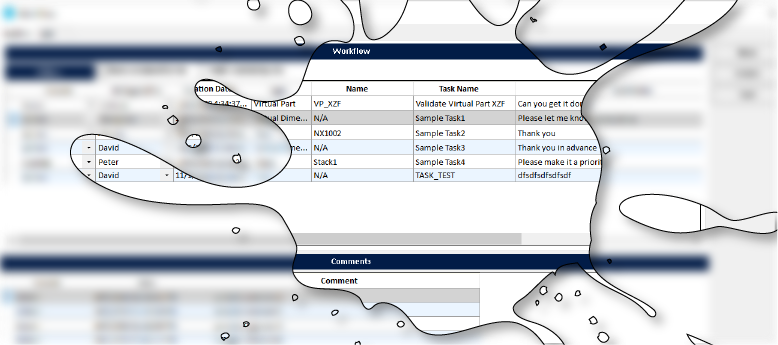

Automatic Stack Updates

The benefits of this centralized system allow for:

Automatic detection and updating of modified dimensions

Detection of stacks containing modified dimensions

Automatic updating of stacks & results

Reduces the chance to make mistakes by reducing manual intervention

The same revision level is used by all engineers

Smart device integration using the iOS App

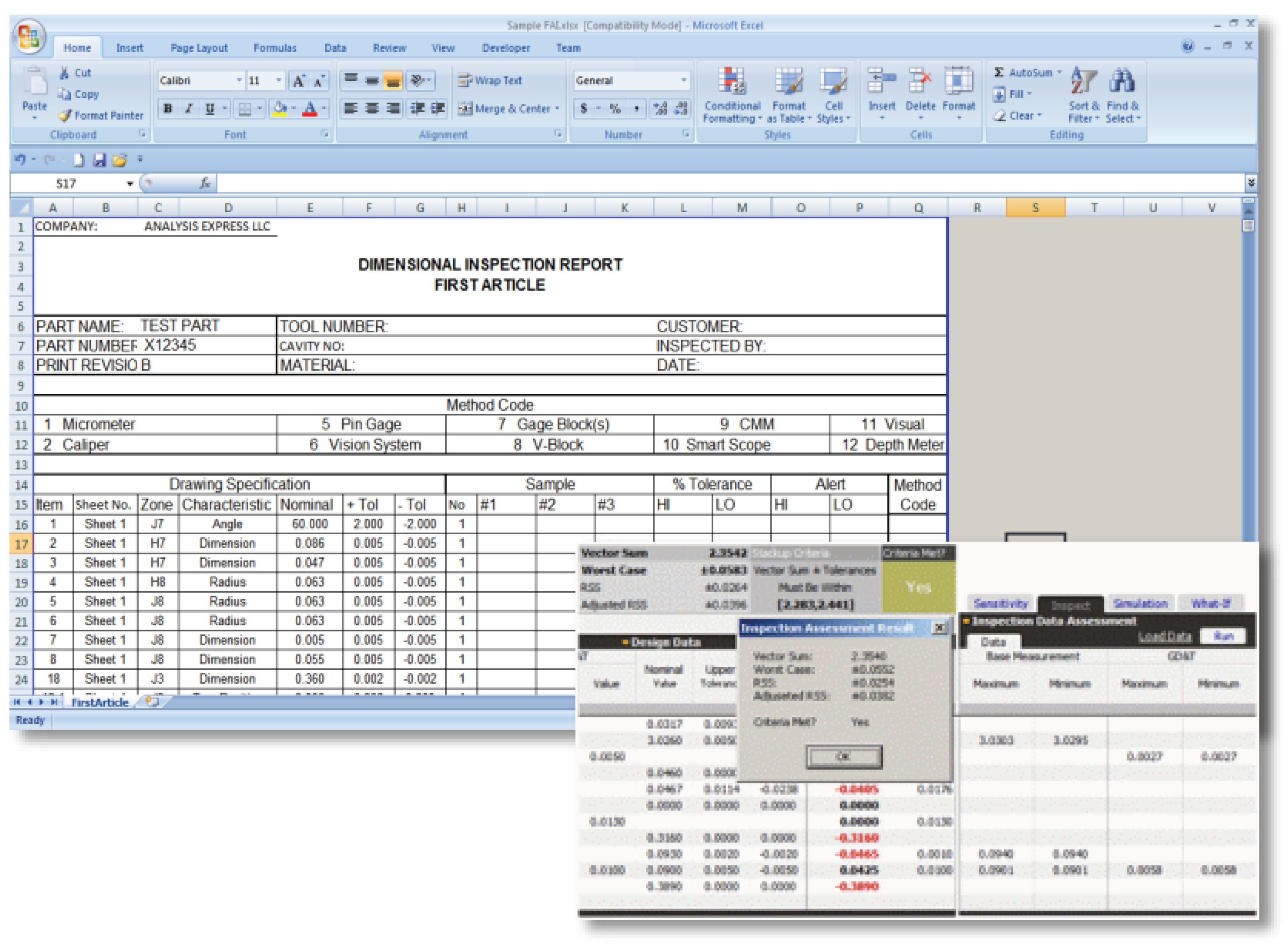

Inspection Data Management and Assessment

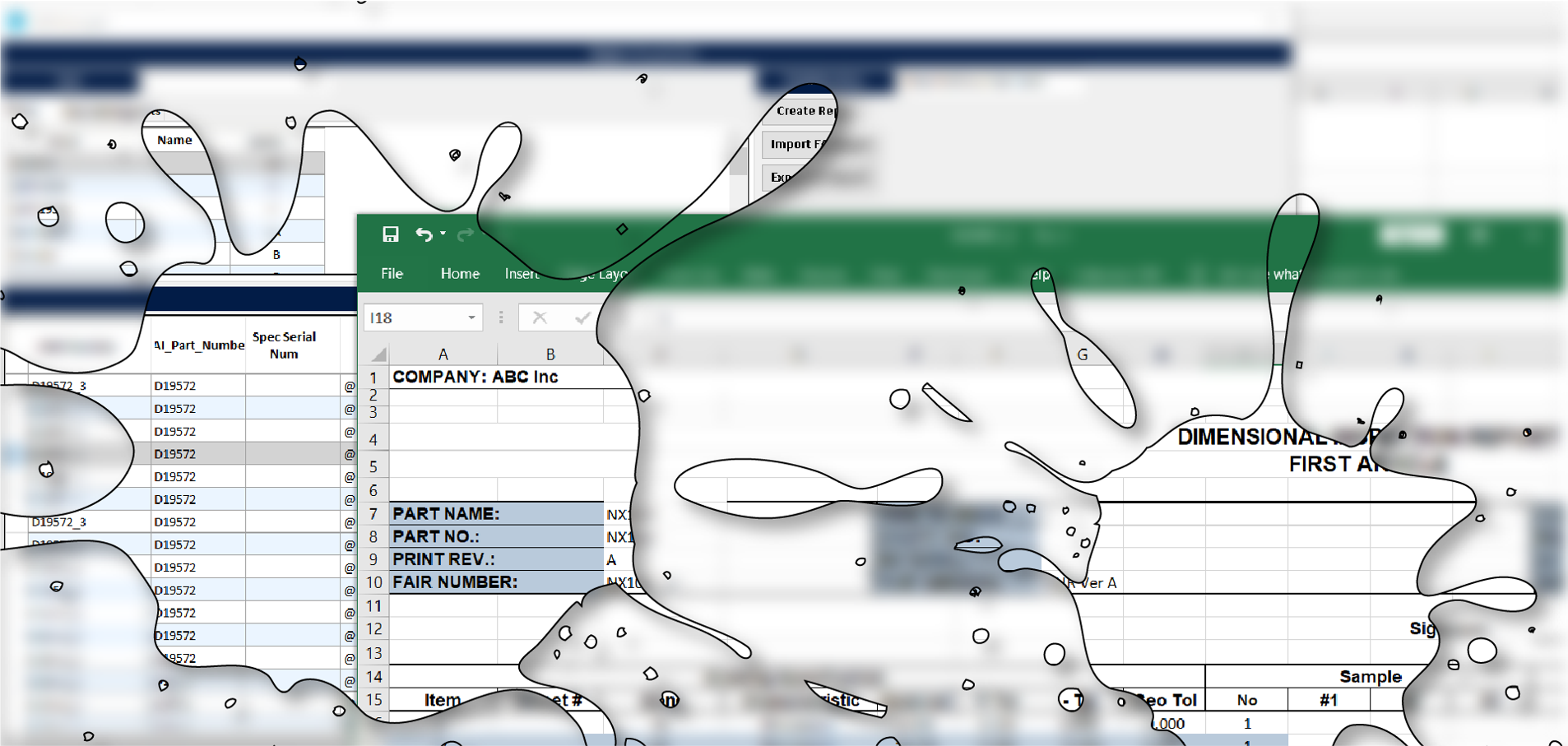

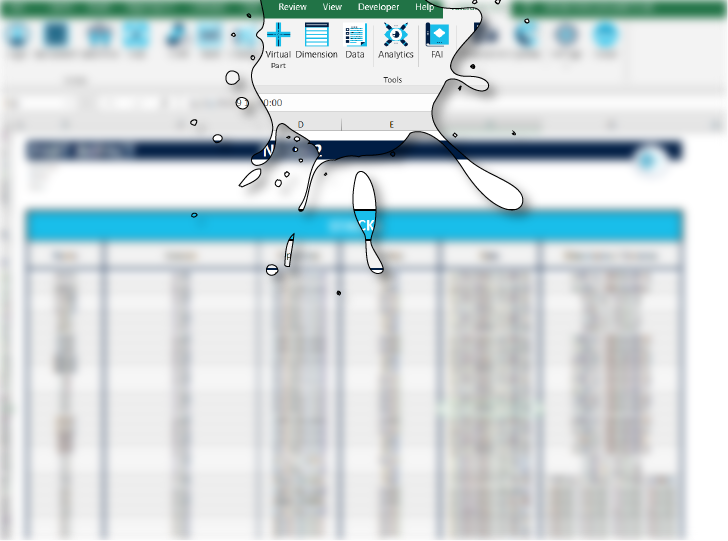

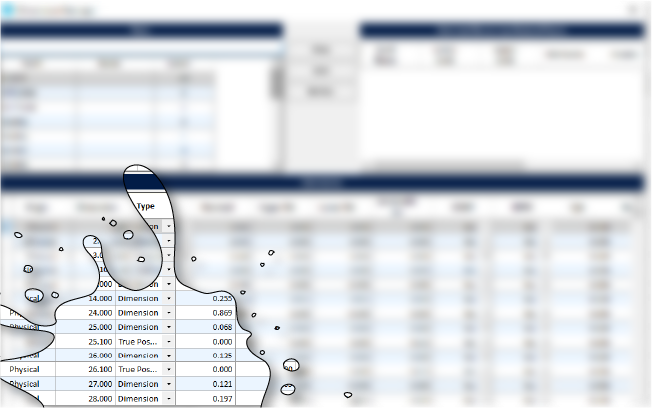

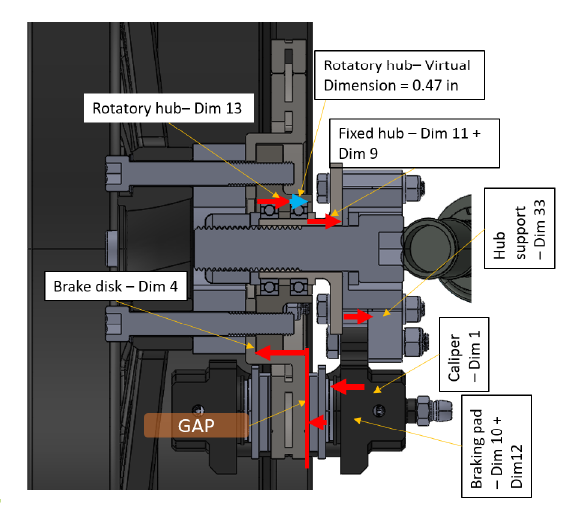

A major benefit of this system is that First Article Inspection (FAI) data can be stored, managed and assessed much more easily. With this system, FAI reports can be prepared with the click of a button. Suppliers can fill in the inspection data quickly. Then the data can be imported back to the central T360 warehouse, allowing engineers to compare and simulate the tolerance stacks with the FAI data and the original design requirements. This helps engineers manage non-conforming requirements, relax tight tolerances on non-critical parts to cut the manufacturing costs, and also reduce design cycle time with the as-built FAI data incorporated into the design process.

Advanced Analyses

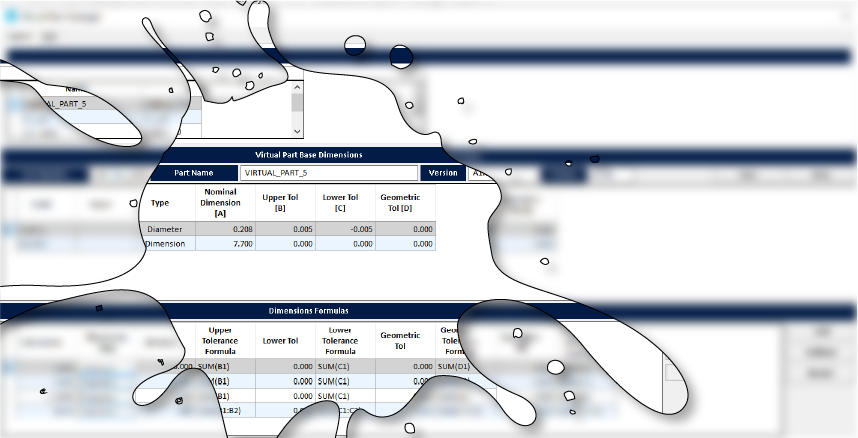

T360 is far more than a standard tolerance analysis solution. The application provides advanced and powerful tools to fine-tune Tolerance Analysis for higher accuracy and better cost-effectiveness. Some of these advanced tools are as follows:

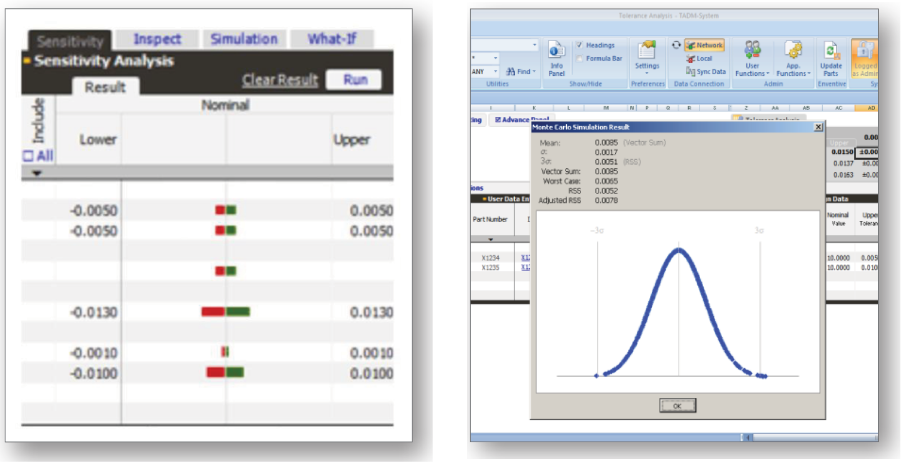

Scenario Analysis

allows the engineers to realize possible impacts on the current stacks and/or all existing stacks if changes are made to the design

Sensitivity Analysis

allows the user to quickly recognize how each component/part can impact other components /parts on the same tolerance stack

Monte Carlo Simulations

allow the users to perform advanced statistical Tolerance Analysis on the tolerance stacks whose components/parts may have different levels of process capabilities and on the non-linear tolerance stacks whose standard RSS method cannot provide accurate results

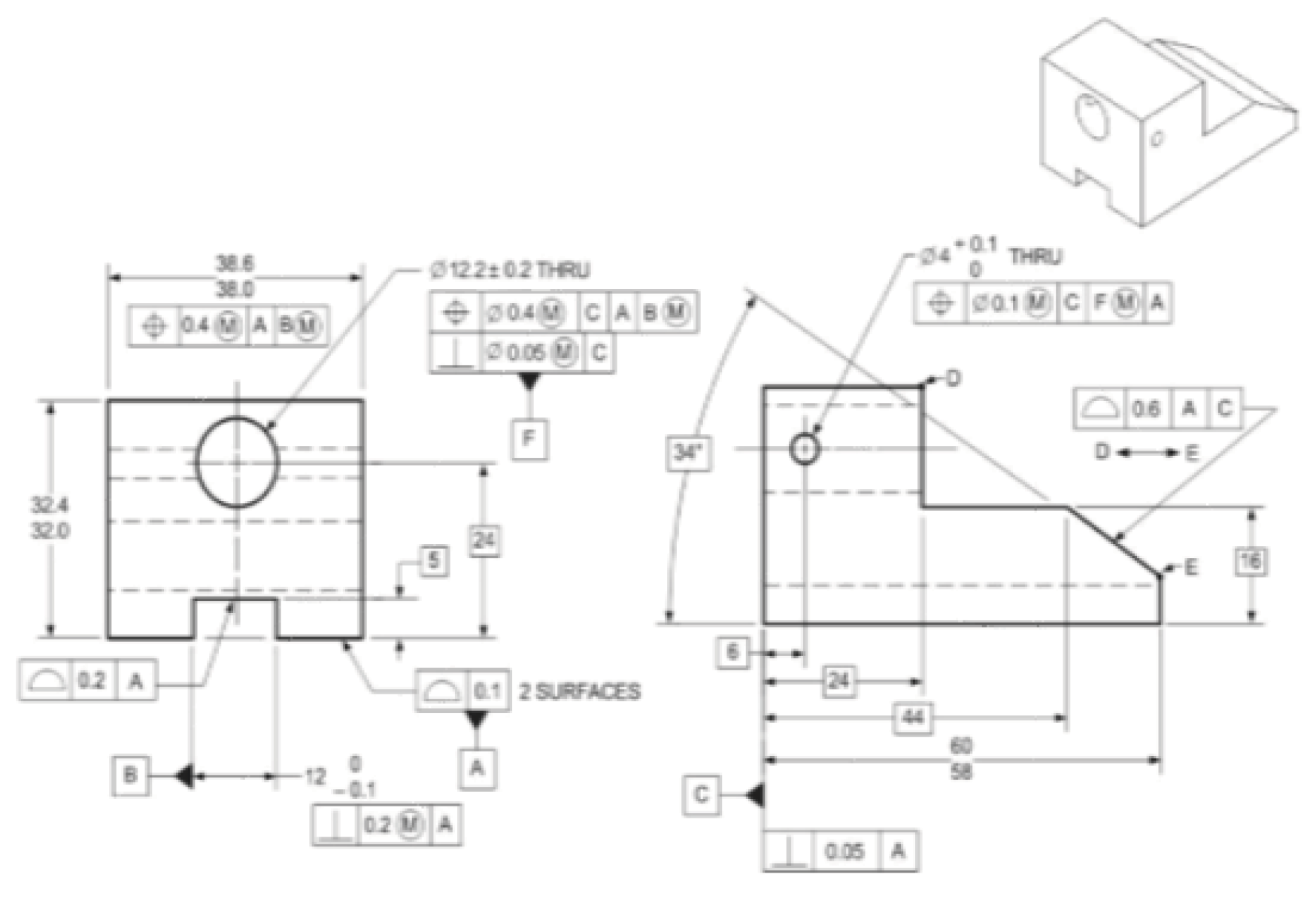

Incorporation of Full GD&T Requirements into Tolerance Analysis

The system provides GD&T capabilities in its tolerance analysis application. The predefined rules and formulas to handle GD&T-based tolerance analysis are stored in the database. The application is dynamic enough to automatically apply these rules and formulas to the basic dimensions and geometric tolerances in conjunction with associated GD&T requirements if they are applied.

T360 Takes the pain out of Tolerance Analysis

TOLERANCE ANALYSIS & DIMENSIONAL MANAGEMENT SYSTEM

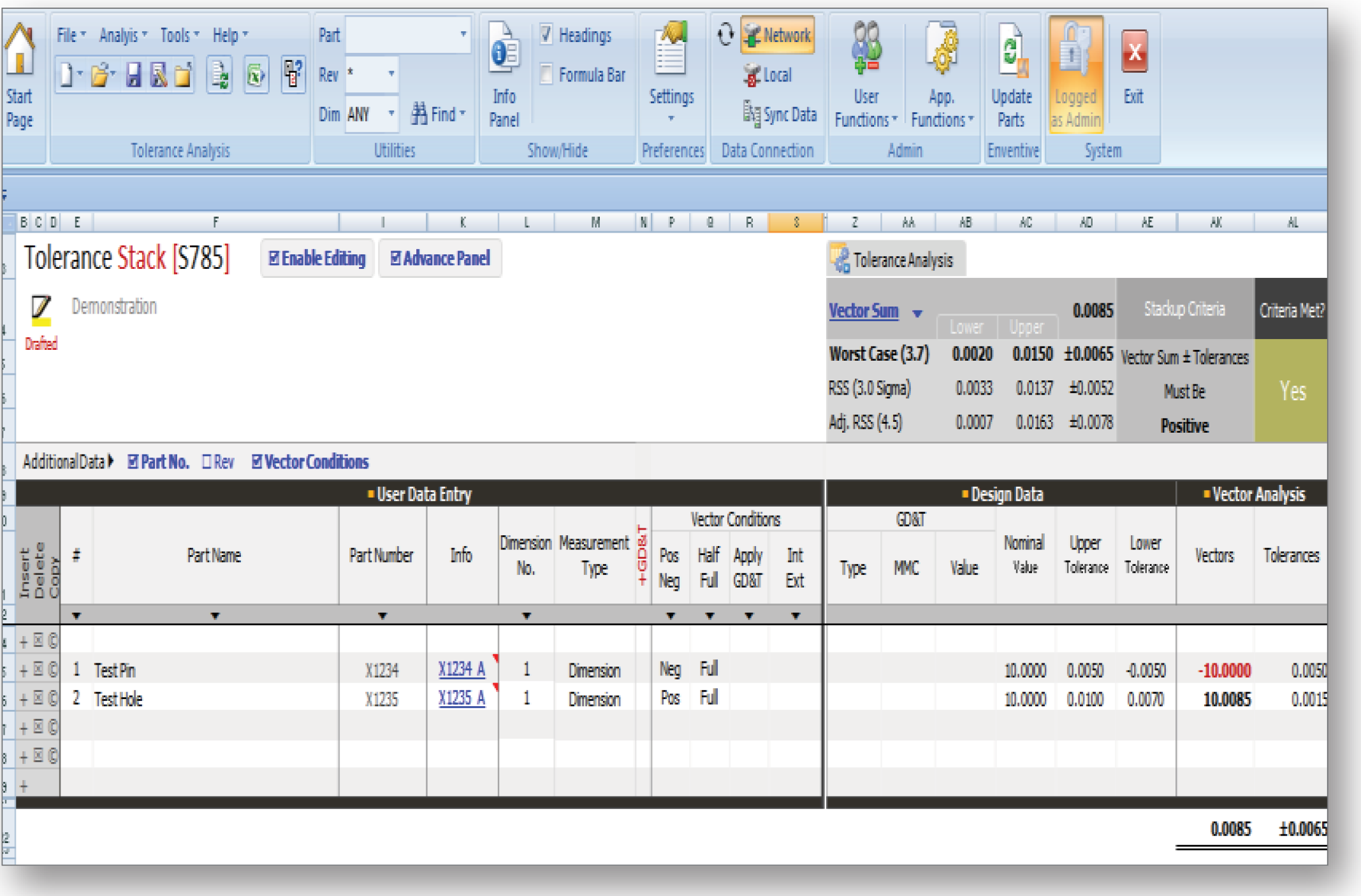

Excel-based Tolerance Analysis Application

.NET APPLICATION DEVELOPMENT FRAMEWORK

COMPLETE SUITE OF INSPECTION DATA MANAGEMENT

T360 Connects All Parts of the R&D Process

More Features

Ease of Use

The interaction interface of the T360 software is intuitively simple and common – it’s Microsoft Excel. Studies have found that most design engineers use Excel to perform tolerance stack-up & analysis. So, T360 takes advantage of this tool, thus providing an interface that users are already familiar with.

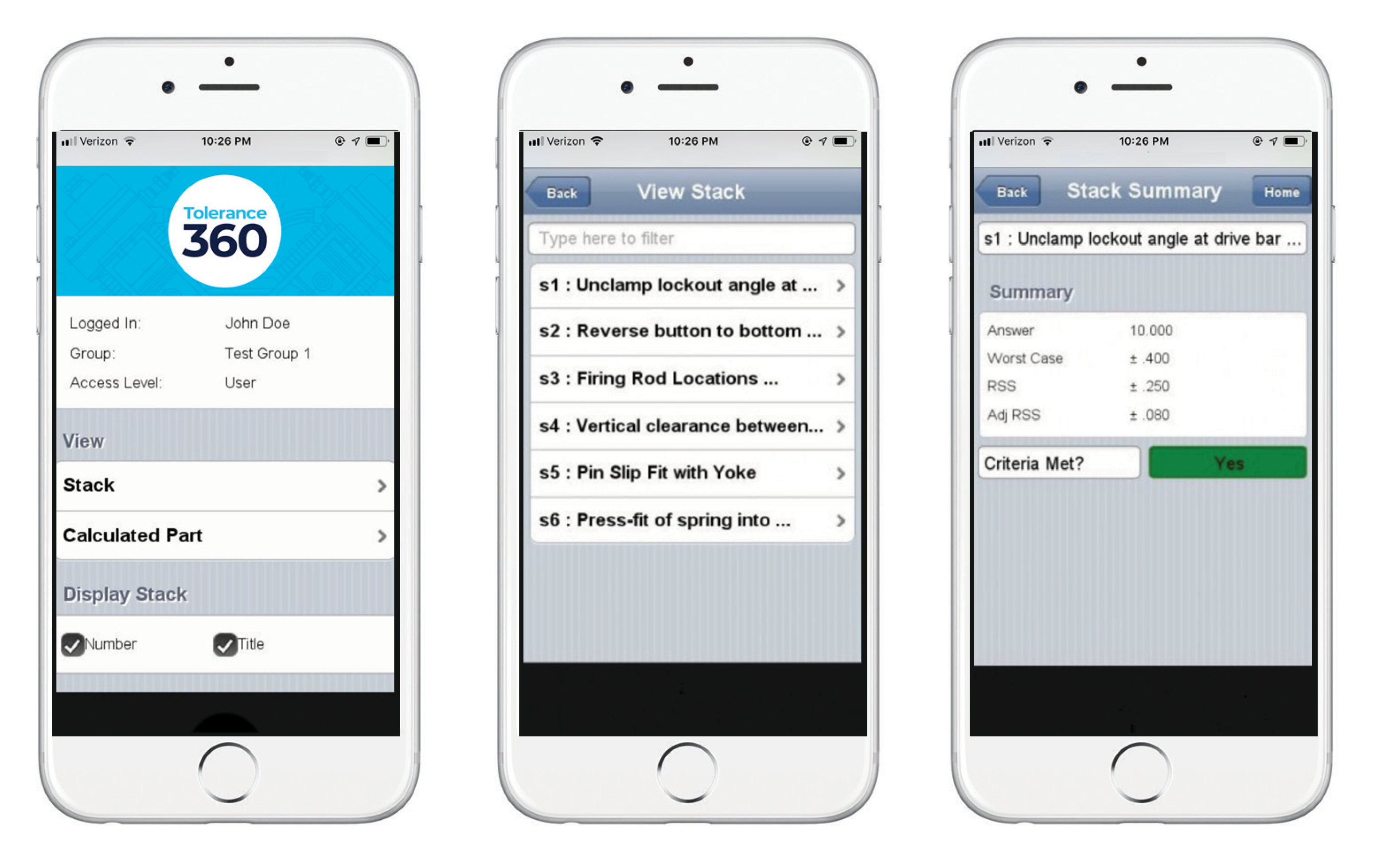

iPhone App

Dashboard reporting and high-level summary information is available via the T360 app for iPhone users. This complimentary software module lets engineers keep essential and critical information at their fingertips when a full version of the software is not needed.

Sophistication of Database System

At the core of this system lies a sophisticated database to warehouse complex application logic, volumes of part records, and tolerance analysis information. This enforces the standardization and centralization of design requirements, inspection data, and tolerance analysis information in one application, one storehouse with one version of truth. Such a bold feature helps eliminate confusion, reduces the hours needed to maintain and update a multitude of stacks, and shortens the design cycle time when as-built inspection data can be incorporated into the design process.

T360 vs Manual-intensive Processes: An Example

Let's Do This!

Why Choose T360

- $Practical solution for tolerance, FAI, collaborative tasks

- $Sophisticated analytics

- $Save time - bring quality products to market faster.

- $Easy to learn and use

Do You Need Help?

Send us a message - we'll be in touch shortly.