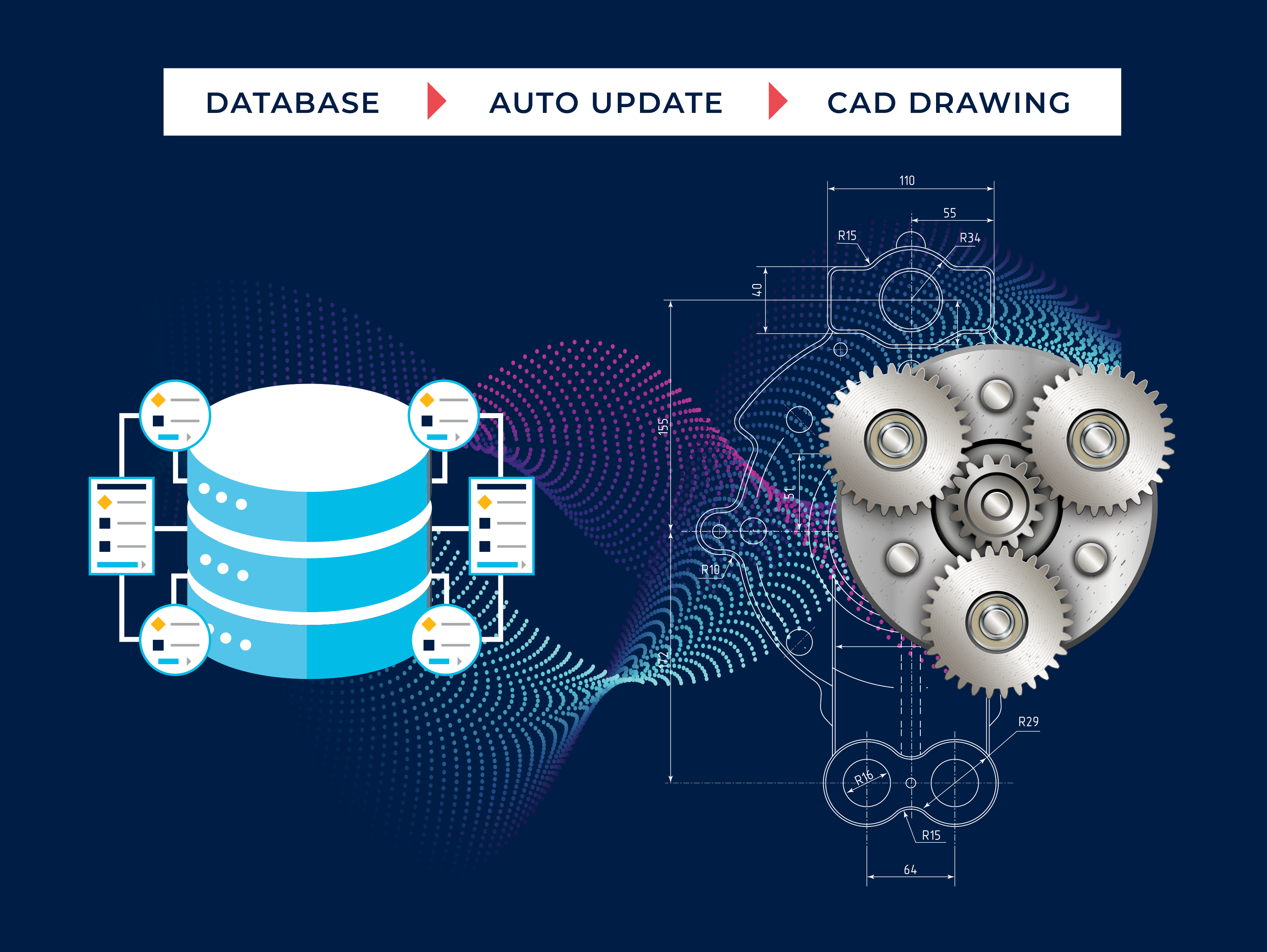

Tolerance360 is the world’s most advanced tolerance analysis management software. Its approach is a paradigm shift that replaces manual-intensive processes. One of the most powerful features of T360 is its ability to automatically update stacks whenever a design change is made. Build your stack once and let T360 take it from there!

T360 vs Manual-intensive Processes: An Example

How it works

Because of T360’s powerful, centralized database backend, it has the ability to compare any changes made in the CAD design to any current and previous affected versions of stack assemblies. T360 also has the ability to find any stacks across the entire enterprise where these changes could have an effect. The system has the ability to flag any stack calculation results that no longer meet the required criteria and alert the users of the issue. This also allows for easy tracking of multiple versions of stacks and their history and ensures that the proper current revision level is being used by engineers.

Let’s say Part 1 is one of the 2000 parts your company makes and has been used in 500 tolerance stackups. Now, you have found an issue with Part 1 and made a change to the part design to correct it. The problem? Now you have to look at 500 tolerance calculations and make sure all the stack calculations are updated to accommodate changes to the part.

With many cups of coffee and long workdays, you will get it done for sure. But with the sheer number of calculations involved, mistakes can creep in. There is no guarantee it’s all correct. You get the new intern to double check all the results. All together, you have used a major part of the week to get one change to take effect. And that’s just a single part! It’s not uncommon to make 50+ changes of a design during R&D of a product.

Why it matters

By providing automatic tolerance stack updates, T360 reduces the number of mistakes that can be made by reducing manual intervention. This leads to improved quality assurance and increased time savings as the system can update its data in seconds and save valuable engineering resources for other important organizational needs.

It’s simple math. If one change takes 40 hours to implement, you would save hundreds of engineering hours if you could automate the process. T360 does just that.