Tolerance 360

Connect the dots between Design, Manufacturing and Quality Engineering

What We Do

Tolerance360 is the world’s most advanced collaborative tolerance analysis software. Its approach is a paradigm shift that replaces manual intensive processes.

What It Does

Tolerance360 seamlessly integrates all aspects of tolerance analysis – from design to manufacturing to quality engineering. The System manages and automatically updates part design, actual inspection data, and tolerance analysis results to drastically improve design process efficiency by connecting the dots between CAD design, manufacturing, and quality assurance.

Value

How T360 Can Help You

Save Time

Cut Costs

Track Versions

Model Scenarios

Reduce Labor

Accelerate Design

About

How It Works

At the core of the T360 software is a sophisticated centralized knowledge engine database that holds parts data, complex analysis logic, and information about all tolerance stacks. The system is capable of understanding and assimilating inspection data. All interaction with the T360 system is done via the familiar and widely popular Excel interface.

Designer

Data Manager

BOM

Drawing Manager

Quality

Analytics

Reports

History

FAI

Engineer

Stack Build

Stack Auto-Update

Virtual Part

FAI

Analytics

Report

History

MonteCarlo Simulation

Scenario

Contribution Analysis

Virtual Parts

Search

Supplier

FAI

Manufacturing

Manufacturing

FAI

Tolerance Management System

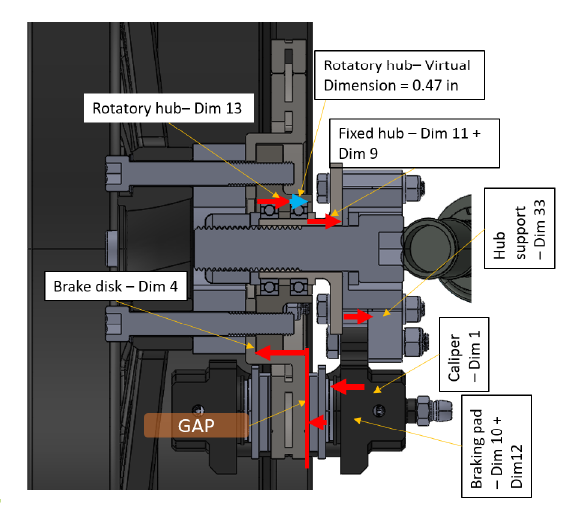

T360 is a data management system implemented to standardize part design, inspection, and tolerance analysis data. T360 stores all information in a centralized data warehouse so that information can be accessed, managed, verified, analyzed and updated more easily.

Familiar Excel Interface

T360 is an Excel add-in and uses the familiar Excel user interface. T360 is feature rich with advanced analysis (e.g. statistical analysis), sensitivity analysis, and scenario analysis. It is capable of handling full GD&T requirements.

.Net Application Framework

The T360 framework can communicate with other engineering and tolerance analysis applications. As such, Tolerance stacks or engineering drawings in other applications can be accessed and updated from within T360.

Inspection Data Management

With T360, First Article Inspection reports can be created, filled out, and imported back to the central data warehouse with ease. This data can then be used for tolerance analysis and for other design and quality engineering purposes.

Step by step

Get Started

Step

Virtual Assessment

Step

Implementation

We optimize and integrate T360 for your

operational environment.

Step

Support & Maintenance

We provide support, enhancements, and T360 engineering talent to improve efficiency within your business.

Let's Do This!

Why Choose T360

- $Practical solution for tolerance, FAI, collaborative tasks

- $Sophisticated analytics

- $Save time - bring quality products to market faster.

- $Easy to learn and use

Do You Need Help?

Send us a message - we'll be in touch shortly.