What if building complex products was as easy as dreaming?

The reality of engineering design is sometimes harsh. Once the product dream is visualized, putting it into practice is not an easy task. Things rarely, if ever, come together on the first go. Design changes are inevitable as the project is built and tested. Depending on the project, every design change may require hours of work or many trials to make sure it will fit. Doing it once is hard enough; doing it over and over can be painful. We all know this.

Thankfully, time-consuming manual design changes aren’t the only option. This is where simulation and modeling comes in. With simulation and modeling, you can more quickly figure out the perfect measurement for your stack.

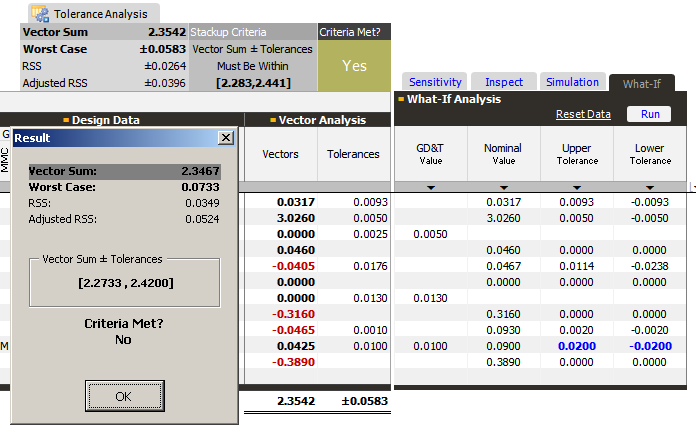

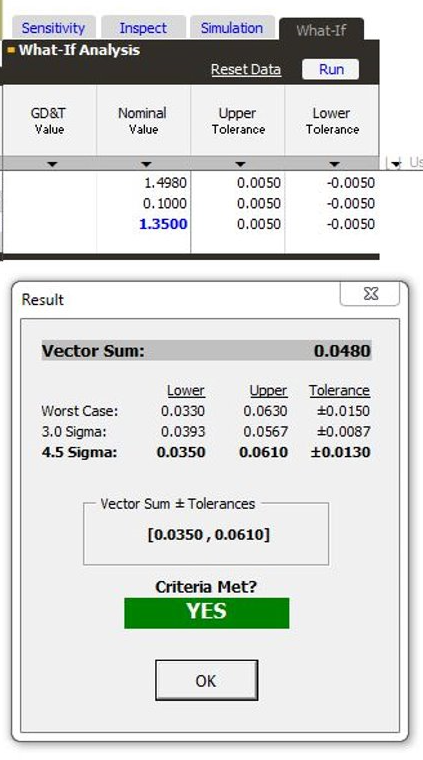

In Tolerance 360, the quickest version of simulation is called What-If Scenario analysis. It’s as simple as imagining dimensions for the software to try and letting T360 figure out the rest.

One of the top features of T360 is the ability to perform a What-If analysis on an existing stack without actually changing the original data. Instead of engineers having to go to a designer to create changes, an engineer can modify the existing tolerance data within a current stack and create a copy of the tolerance data that can be manipulated to preview potential acceptable changes to all stacks in the database.

Engineers can quickly modify tolerances and nominal values to see if these changes will be acceptable and to meet the proper design criteria. This provides huge time savings over the traditional R&D process.

Whenever changes are made to any numbers in the What-If table, these changes will have BLUE fonts.

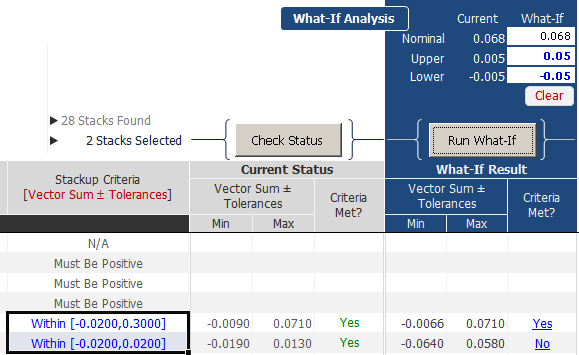

What about multiple stacks?

Users can also run What-If analysis on multiple stacks. Once all the found stacks are listed, users can select a certain number of stacks to perform a stack check and what-if analysis. Users can select stacks by highlighting.

When a number of stacks are selected, the Check Status and Run What-If buttons are enabled allowing users to check the status and results of the selected stacks and to perform the What-If analysis based on the What-If values as shown in the picture below.